For once we can say that the weather has bought out the cars and its great to see them on the road. It makes a change from us saying a couple of months back drive carefully in snow and ice. Speaking of driving carefully brings us onto our Park & Pic this week;

Park & Pic

Our friend and loyal customer Mart D. has finally got his car out the garage to get it M.O.T’ed with us. We know that the car’s MOT had run out in early December last year and has been SORN (Statutory Off Road Notification). In the mean time his car has been wrapped in cotton wool in the heated and dehumidified garage of his. Mart and his OCD issues wouldn’t allow him to bring it out in the rain just in case it shrunk apparently! Still it’s nice to see his ’66 Coupe in Acapulco blue in the sun, it’s just we are not on holiday in the real Acapulco, Mexico. We have done an extensive guide of the full restoration of his car from being a real mess of a shell, to being at the NEC Classic Car Show some four years later when it was finished. Click here for the link to see all the work. It’s a very large page so give ita few moments to load.

The car had a time slot with our MOT guys, trouble was that Mart would be driving it there. Let’s just say that he is worse than useless with directions, he has even got lost with a Sat-Nav (honestly). All of this is being said with Marts knowledge and he will be the first to admit it as well. 😀 Anyway we gave him the Sat-Nav details, we gave him verbal description on how to get there from both Adam and Morgan. With that he set off at about quarter to eleven for the fifteen minute journey. Just as he was leaving Yogi sent him a message to remind him that the MOT centre shuts at three pm on a saturday, therefore he would need to get a move on. 😀 Anyway twenty-five minutes later we got the text to say he had found it and was feeling very proud of himself! Apparently he had driven carefully watching “The other nutters on the road who were intent on trying to mash my motor up.” Again, those we only printable words we could use on a family blog.

A little while later the car had passed with flying colours and he was on the way back to us. There was a tiniest leak from the water thermostat housing that needed a little tighten up. Mart got stressed about it as he had to clean that part of the engine (again). This is fairly common as the chrome housings can go slightly out of shape causing a tiny drip now and again, which only needs a little tighten up to reseal again.

Customer Cars

The Gold Convertible has been for the initial road test and things didn’t go to plan. Yogi took her round the usual route, country lanes for handling, dual carriageway for a cruising test and round abouts and junctions for brakes.

The car was tuned to default and the road tes started. Once the car got onto the main dual carriageway there was the dreaded drone and an increasing wobble on the steering. Front wheel bearing had decided to implode. Yogi being on the ball pulled over immediately and stopped and noticed the smoke from the hub of the wheel. As LAR headquarters were only a couple of miles away now a recovery was required to prevent more damage. The car was put straight back into the Yogi cave where the strip down started to get the bearing off and this is what was left after the race and bearing had destroyed each other. Not the nice neat unit you would expect. Although it was all greased you just need one rod to fracture and it will take everything with it. Not every single road test goes to plan, That why we do them – to make sure we are happy with it before we hand it over. The good part is that it happened to us and we managed to not damage the spindles as we knew what was going on. This could have happened at any time and there is no way to predict a bearing failure of this proportion unfortunately.

Now we would have to replace the wheel bearings on both sides and the steering realigned as a result.

The car would then take another road test to check the wheel alignment and make sure all was OK once again.

As the sun was out we put the roof up! Yep UP. That way the warmth of the sun can help stretch the stiff new material into place and help the folded creases to fall out too.

Other News:

Adams new purchase is this little rarity anybody recognise it?

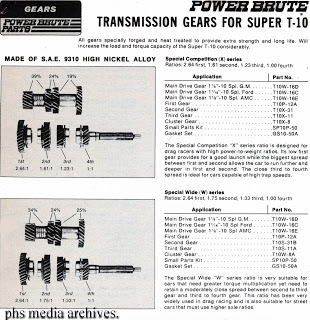

This is one of those rarity gearboxes; a Super T10. We found this information on the gearbox and it’s background and why it’s such a sort after gearbox. We thought we would give you a little techy article post which we found on a Borg Warner Tech spec site;

One of the earliest models to get the four speed was the Corvette. It appeared in 1957 and helped make it a real sports car contender along with the 283 V8. What engineers did was use the T-85 main case and add a reverse gear into the extension housing, making room for fourth gear. The main cases were aluminum on Corvettes. Other Chevrolet cars used cast iron cases until 1962. The T-10 was considered a heavy-duty transmission at the time and was issued with high performances engines of the early 1960s. You’ll see these behind 283 fuelies, 348s, Pontiac 389s and even Mopars used them until their own unit was ready in late 1963.

One of the earliest models to get the four speed was the Corvette. It appeared in 1957 and helped make it a real sports car contender along with the 283 V8. What engineers did was use the T-85 main case and add a reverse gear into the extension housing, making room for fourth gear. The main cases were aluminum on Corvettes. Other Chevrolet cars used cast iron cases until 1962. The T-10 was considered a heavy-duty transmission at the time and was issued with high performances engines of the early 1960s. You’ll see these behind 283 fuelies, 348s, Pontiac 389s and even Mopars used them until their own unit was ready in late 1963.The Super T-10:

Competition ended the T-10’s domination in cars. Muncie, Saginaw and New Process all developed their own four speed boxes, each capable of handling high torque and sustained power. By 1965, wide-spread use of the T-10 was easing. Buick held on until 1966 and Corvette remained the sole factory player by 1967. The story doesn’t end there. Drag racing uncovered some weaknesses in the original design and research efforts by many racers developed new tricks to improve the basic design. This and a selection of different gear clusters kept the T-10 active. A result of all this R&D was the release of the Super T-10 in 1969. This revised transmission had an iron main case instead of aluminum. The gear sets were larger than the originals for added strength yet were smaller than either Muncie or New Process gears. The Super T-10 gears were 9310 high nickel alloy and were coarse cut for better load capacity. You also got more ratios to pick from.The Super T-10 was sorely needed as muscle cars were very powerful by the end of the decade. More changes were made in production and an aftermarket over the counter version was offered called Power Brute. You could order new ratios, heavy-duty synchro sleeves and generally improved parts. The GM Super T-10s were about 92 pounds while big car Ford Super T-10s came in around 101 pounds.

Ford used three versions of T-10s in their cars. The light cars used a 2.73:1 low gear, 2.06:1 second and 1.62:1 third gear. As in all other applications fourth gear is direct drive. The big block Galaxie used 2.36:1 low gear, 1.62:1 second gear and 1.76:1 third gear. The third Ford T-10 used 2.36:1 low gear, 1.76:1 second gear and 1.41 for third gear.Mopar T-10s: Chrysler used two different gear sets for their T-10s. The standard set was 2.54:1 for 1st gear, 1,89:1 for second gear and 1.51:1 for third. The close ratio set was 2.20:1 low, 1.64:1 second and 1.31 third gear.

Classic T-10 Mods from the 60s & 70s: The aluminum main case is a bit fragile for heavy race use. The gear shafts are prone to flexing under high loads. This is one reason why the Muncie and especially the M22 was preferred equipment and still highly desirable to this day. While Borg Warner didn’t release a high twist gear set like the M22, they did come up with a second revision Super T-10 in 1975. The Super T-10 gear shafts are tougher as they’re made from high nickel content. For a brief period it was the hot set up to install Super T-10 shafts inside an aluminum main case. You saved about 30 pounds but had to go through the expense of modifying case to fit a late-model shaft. Wear rate increased because the nickel shafts could crack the trans shift cover, then your case in that order. This mod was dropped after a few years. Another more worthwhile tip is using the Ford T-10 shifter arms and shafts. They used a 3/8-inch stud which is thicker than the 5/16 GM shafts. If your T-10 has the older bearings with non grooved sleeve go for an upgrade. Borg Warner has used the heavy-duty bearings since 1975. Power Brute aftermarket bearings were available starting in 1972 and have appeared in some production cases. For GM cars, the Buick 27-spline main shaft takes high rpm launch stresses better than Chevrolet main shafts.

We finish with a couple of nice pics where Adam says make sure your dogs have plenty of clean fresh water in this heat, looks like they are enjoying the sun too.

Good to see my little ol’ car on Park n Pic. Thanks guys for looking after her for me.

LikeLiked by 1 person

About time you got the car down here. LOL.

LikeLiked by 1 person