We have an update on the move to our new location, well hundred meters or so to the yard at the back. We have almost finished moving the stock from the old offices and storage rooms to the secure locked containers. We have found lots of items that we have never gotten around to adding to our stock lists. We are adding some of these items to our ‘Clearance Sale Items‘ page click here for the link. Once these items are gone, they’re gone. It’s worth checking in everyday if you are looking for a bargain or replacing that part that just needs a little upgrade.

The new storage containers are getting their proper lighting install and we can fianly say that we are there. All the stock locations have been updated on the systems, with the more commonly ordered parts close to our parts counter. When browsing our WebShop, if the item says ‘Currently In Stock’, then there is no need to email us, trust us it’s in stock!

Just a few of the containers with the remaining stock going in. We have a new stock of radiators and some consumable sundries as well, we think Adam may have over ordered to fill the latest delivery pallet up. All our sheet metal is housed elsewhere in a controlled environment where we have a much bigger storage areas to pick the panels when we need them.

Restoration Parts

As we are scaling back on the new restoration projects and getting older (according to Adam),we are moving into a more specialist area for some of our parts. We can restore some of the original parts for the connoisseurs clients who want original parts and the best finish and of course the perfect fit just like of the production lines. In our new office we have a display cabinet that contains a couple of restored dash panels and some carbs with various finishes.

The dashes have been finished in a couple ways, on the rears cases one is zinc plated, the other is painted, both to the highest quality. These restorations are not to be confused with the more common reproduction parts. The amount of work that goes into creating these zinc plated or painted restored quality parts, in our opinion they are a better than the OEM at the time, that all comes at a price. If you want the best we can custom restore some items, if you are interested send us an email and we can advise if it’s possible and how much for such a niche service. If you are picking up some parts from our sales counter, you can ask to have a look at the quality of these parts as the pics honestly don’t do them justice.

Carburettors

We have also finished some OEM carbs that have been completely stripped, cleaned, rebuilt and finished in nickel.

It’s notoriously difficult to zinc plate aluminum and these OEM carbs are no exception. However when done properly to our own specifications, they will add that extra look of quality under the hood.

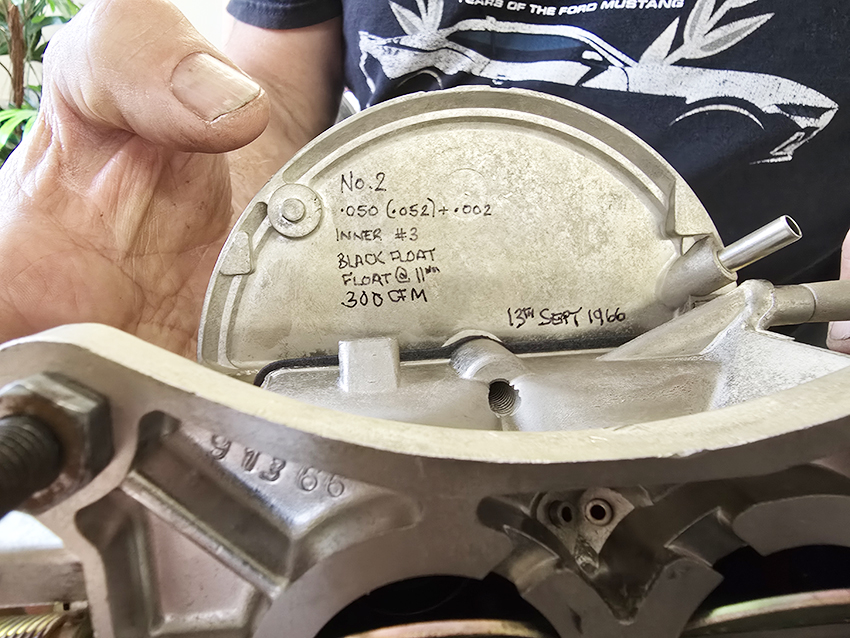

Each carb that we rebuild also comes with it’s own unique specification so you know exactly what you are getting, with a default setup tune.

This zinc finished option carb is another option if you want a different style of finish. Again each one is unique and could set your pride and joy apart from other other cars with a similar setup.

These carburettors will not oxidise again in our lifetimes. They’ll remain with this level of finish, which is not only aesthetically pleasing but also helps cure a potential problem for seasonally used cars. As the “off-season” oxidisation that could occur on the exterior but more importantly, in the float bowls in damp or musty storage, could find its way into very narrow fuel passages, it could limit performance. The only “garbage” you’ll find in the float bowls will be very fine sediment that’s passed through your fuel filter from your tank or fuel line, not from the carburettor itself.

These carburettors go through 5 levels of cleaning before the surface treatment process. None of which are abrasive, all are done chemically in line with the best electroplating industry processes. The body castings, accelerator pump and power valve housings are all etch cleaned to a depth of 25 microns prior to surface treatment and all the steel parts are zinc plated or renewed.

We have tested one of our own cars with the first restored 2100 carburettor, and once the float bowl was filled with fuel, she fired up and settled to a high idle instantly.

Naturally, no two engines are the same, and these carburettors may need small adjustments to the hot and cold idle speed screws, the mixture screws and possibly the choke index. However, all are set up to exact factory specifications relating to their I.D tag or stamped serial numbers as per Autolites original service literature. Therefore, they should be very close to optimum from the get-go.

The only area of potential concern is jetting. We advise you to start off on the original jetting used with your engine specification. Then, if a change is required, to re-jet in two steps, either up or down, depending if you’re rich or lean. Then, when the fuelling ring on a sacrificial spark plug confirms you’re not running rich or lean under load, the Autolite should “hold its tune” for a good long period.

These are very simple, reliable but quite underrated carburettor. The annular style fuel discharge method (not available in other carburettors of the period) gives better fuel atomization, which leads to improved throttle response, driveability, and performance across a wider range of engine speeds.

Soon, we will also be offering the 4 barrel 4100 version too. At first for bigger engine owners (351ci to 390ci) as the 4100 came mostly in two different sizes, 485cfm and 600cfm. The 600 models are more widely available. However, theyre not all the same and are more complicated to get to work efficiently on anything around the 302/289/260 cubic inches ballpark but it is possibly, we know how, we just need a constant stream of reliable parts that require changing. When we have that in place you’ll see it announced on our blog.

We are aiming to have completely relocated all our stock to the yard area over the next week or so. When ordering nothing changes for our customers, it just means Gary may have to walk back and forth to get those obscure parts.

Stay Safe & Take Care!

Some awesome work with the finishes. The cost shouldn’t be a problem if an original part looks that good to be honest.

LikeLiked by 1 person

TO make things look that good people don’t realise just how long it takes to clean, test and then start the finish processes. We started doing them again as the request for original parts that look good is increasing. Repro parts will do the job, but nothing works as OEM should. By the time we finish with these they are better than the OEM stuff.

LikeLiked by 1 person